Hydraulic cylinders

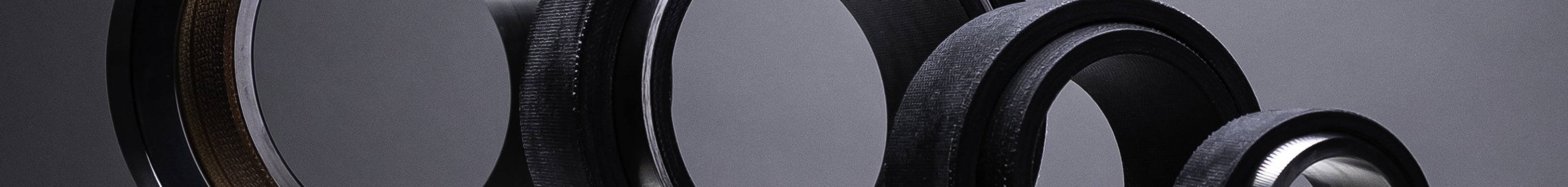

Many spherical plain bearings are used in hydraulic cylinders, mostly for oscillating movements.

The following gives an overview of applications in which these bearings are used:

Difficult to lubricate and seal

Lubrication devices and external seals are costly, susceptible to failure and require periodic maintenance. They are often in locations which are difficult to access (cranes, lock gates) and increase the design costs of the construction. Furthermore, lubrication devices are often the cause of environmental pollution, due to the outbound flow of lubricant. By using a Feroball® bearing, it is often possible to design an application that does not require these devices.

External application

If cylinders are to be used on ships, whether submerged in or out of the water, it is very important that the bearings are moisture-resistant. Even if the application is designed to protect the bearings against moisture, failure due to corrosion cannot be discounted. Material choices such as composite and stainless steel (1.4404) guarantee good resistance to moisture and corrosion and therefore result in a high degree of operational reliability. In many cases, conventional spherical plain bearings do not meet such exacting requirements. Bearings with a metal-to-metal sliding surface require lubrication and, as a result, are not corrosion-resistant. Furthermore, bearings with a PTFE sliding surface are not sufficiently resistant to moisture and contamination and, as a result, are susceptible to increased wear. In the event of absent or insufficient maintenance, environmental factors will have a detrimental effect on the lifetime performance of the bearing. Feroball® bearings are an excellent alternative for all operating conditions.

Hinged constructions

Feroball® spherical plain bearings are also frequently used in hinged constructions, for example in large cranes, valves or in drawbridges.

In these cases, the bearings are required to operate under the following conditions:

Extremely changeable weather

Many of these constructions are exposed to changeable weather conditions. As a result, the bearings must be resistant to temperatures ranging between -30 °C and +50 °C.

Minimal angular rotation under constant load

Hinged constructions are subject to minimal angular rotation under constant load, resulting in the lubricant being squeezed from the contact surfaces. As Feroball® bearings contain lubricant within the composite, the lubricant is retained for longer on the contact surfaces.

Fluctuating loads

Hydraulic cylinders move back and forth, resulting in fluctuating loads on the bearings. The application of load to the bearings is constant but varies in magnitude, for example in the case of cranes or heavy bridges. Consequently, it is highly beneficial if the bearings exhibit damping capabilities. By using a composite ball and stainless steel rings, the peak loads are absorbed in the bearing.

Very low dynamic loads

In several bridge concepts, over-dimensioning can present considerable problems for the pivot points. As a result, the correct surface load in the bearing is not achieved at start-up and the bearing cannot be pushed through the breakout moment. As a hydraulic installation does have the power to press through, a vibrating movement (shocking movement) is triggered in the construction. The load increases in the hydraulics and the bearing moves and then immediately comes to a standstill. This limit is known as the stick-slip limit. Feroball® bearings are designed specifically for these circumstances and are able to function at very low surface loads. If this is still not sufficient, a special bedding-in-paste can be applied. The running-in period of the bearing is therefore accelerated, causing the sliding resistance to decrease even more rapidly. Feroball® bearings offer an extremely good solution for such conditions.

Other possible applications include:

Bridges

- Main pivot points of the deck

- Cylinders

- Hanging rods

Locks

- Cylinders

- Main pivot points of the doors

Luxury yacht construction

- Boarding equipment

- Gangways

- Accommodation ladders

- Swim ladders

- Boarding platforms

Doors / blinds

- Tender store doors

- Transom

- Hull side doors

Cranes

- Deck cranes

- Tender cranes

- Offshore cranes

Waterjets